- [email protected]

- +86-156-5921-2309

The application of glow in the dark material materials seems to cover all aspects of life. It can be used as a safety material for various emergency exit signs, such as fire, escape, ship and other escape routes. It can also be used as an accessory material for toys, wall stickers, ceiling decorative stars and moons, picture boards, glow in the dark clothes, and custom cutting various pattern decals, etc.

The glow in the dark material (also known as photoluminescent material and luminescent material) is made of strontium aluminate rare earth material. Strontium aluminate achieves the characteristics of luminescence by absorbing light, sunlight and other light, and then slowly releasing light. It usually absorbs light for 5-20 minutes, and its glow time can be as long as 12 hours. Since strontium aluminate is non-toxic, non-polluting, and non-radioactive, photoluminescent materials are widely used.

According to the main components of glow in the dark material, we know that it is made of strontium aluminate phosphorescent material, since strontium aluminate is non-toxic, non-polluting, non-radioactive material, so we can use photoluminescent material with confidence

At present, our strontium aluminate phosphorescent materials are widely used, and they are used in life through various types of photoluminescent materials.

glow in the dark powder is the raw material of many luminous materials, and can be used for any transparent media such as coatings, plastics, inks, paints, ceramics, glass, fibers, printing pastes, etc. The most commonly used color is yellow-green (green light).

It has a variety of colors for you to choose, and according to your requirements for luminous brightness, you can choose the appropriate ratio to mix it with other plastics to make various plastic luminous products.

Glow in the dark stone is mainly used for ornamental and decorative purposes, and is widely used in various decorations such as fish tanks, flower pots, wishing bottles, as well as trails such as greenways and park trails.

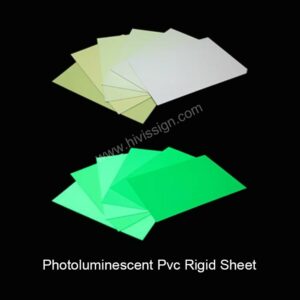

Excellent printing performance, can be customized to print various emergency exit sign through eco-solvent printers, UV printers, screen printing, and are widely used in safety signs, warning signs, and fire signs.

It has the same excellent printing performance as the photoluminescent PVC rigid sheet, and because it is the self-adhesive roll type, it is more convenient to use and more cost-effective, so it is widely used, such as emergency exit signs, and various types of warning stickers .

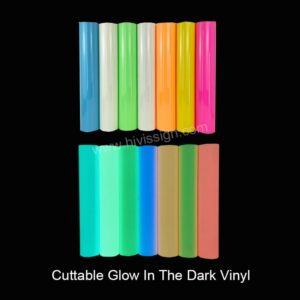

Cuttable glow in the dark vinyl are available in a variety of color options and are easy to cut, and are widely used on a variety of custom glow in the dark decals, such as stars, moons on ceilings, and motorcycle, helmet stickers.

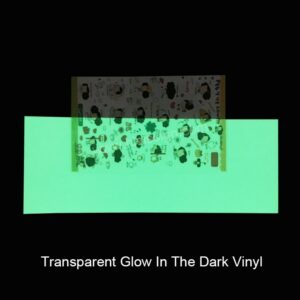

Is transparent glow in the dark vinyl new to you? Its transparent characteristics are often applied to various patterned surfaces such as artworks, photos, business cards, etc.

Luminous is a very eye-catching fashion element, with its application, people apply it in heat transfer vinyl, now we can customize color glow in the dark heat transfer vinyl, holographic glow in the dark heat transfer vinyl, Puff glow in the dark heat transfer vinyl and other DIY glow materials.

Because of its reflective and luminous characteristics, it provides double insurance for safety, and is widely used in various helmet decals, bicycle stickers, and vehicle conspicuity marking.

At present, the most commonly used strontium aluminate materials are mainly yellow-green (green light) and white (blue light), among which the yellow-green (green light) has the best luminous brightness and is widely used in various emergency exit signs.

The Photoluminescent Safety Products Association (PSPA) systematically classifies photoluminescent materials according to their afterglow as follows:

|

Luminance mcd/m2

|

2 mins

|

10 mins

|

30 mins

|

60 mins

|

|---|---|---|---|---|

|

Class A

|

108

|

25

|

7

|

3

|

|

Class B

|

210

|

50

|

15

|

7

|

|

Class C

|

690

|

140

|

45

|

20

|

|

Class D

|

1100

|

260

|

85

|

35

|

|

Class E

|

1800

|

400

|

120

|

55

|

|

Class F

|

2300

|

520

|

155

|

70

|

|

Class G

|

3000

|

650

|

190

|

80

|

The PSPA classification system is based on luminance decay data as given when tested according to ISO 17398 (also ISO 16069) illuminated with 1000 lux from Xenon D75 (Daylight) source for 5 minutes (very similar to DIN 67510 Part 1 and ASTM E 2073-10 also with this illumination and time.

Yes. It is one of the ideal DIY materials.

Such as cutable glow in the dark vinyl roll, clear luminous vinyl, glow in the dark heat transfer vinyl, reflective glow in the dark vinyl, they can all be customized with various patterns through simple equipment. Therefore, it is loved by the majority of DIY users.

For all your glow in the dark material needs from China, contact us now.

Best Retroreflective Material Supplier in China. We will provide you with one-stop retroreflective material procurement services.

We will never rent or sell your email to anyone.

If you are looking for a professional reflective material supplier in China as your partner, FLIGHT is your best choice. We provide retroreflective material that comply with ASTM D4956 standards, as well as custom vehicle reflective tapes according to your country’s traffic regulations