- [email protected]

- +86-156-5921-2309

Heat transfer materials are not unfamiliar to many people, but how to choose the right HTV vinyl will have some questions for everyone. Based on that, we’ve put together this guide to help more people choose the right HTV vinyl. If you don’t find an answer in our guide, you can email us at [email protected] and our team of product experts with over 10 years of experience will work hard to answer any questions you have.

Heat transfer materials are those with a backing that contains a layer of heat-activated adhesive (also known as a hot melt film) that permanently bonds the material to the fabric by heat pressing.

The most common type of heat transfer material used is the film vinyl type, which is also commonly referred to as heat transfer vinyl, HTV vinyl, iron on vinyl, and heat press vinyl.

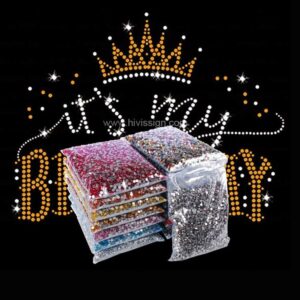

Another application type of heat transfer material is the rhinestone type, which is often referred to as Heat Press Rhinestones or iron on Rhinestones.

Fashion decorative patterns on various fabrics such as shoes, clothing, hats, bags, etc., the common types are printing, embroidery, and heat transfer. Since the printing type and embroidery type have higher requirements on the equipment and also require the operator to have rich industry experience, they are more suitable for industrial production.

For the heat transfer type, only a simple plotter cutting machine and a heat press (or iron) can be used to customize the logo pattern, and it does not require extensive experience, so it is an ideal material for DIY.

In addition, with the continuous development of heat transfer material applications, we now have a wide variety of finishes for HTV vinyl, as well as it also has a variety of material types to choose from.

To help you find the perfect heat transfer vinyl, we’ll be classifying HTV vinyl from multiple dimensions.

At present, the heat transfer materials we use mainly include PVC, PET, PU, silicone, and other material types, of which PU is the most widely used material type. But we have to mention that silicone vinyl applications are on the rise.

Features of Silicone HTV:

● food-grade material

● soft and skin-friendly

● Good elasticity, Washability, no breakage

● Anti-sublimation

So silicone heat transfer vinyl will be the ideal material for more children’s products and brands.

Since heat transfer material is a fashionable decorative material, its finishes determine the cool effect of logo patterns. The richness of HTV finishes is also an important factor that allows HTV to develop rapidly. Common finishes are as follows.

● Matte HTV Vinyl

● Pearly HTV Vinyl

● Reflective Heat Transfer Vinyl

● Glow In the Dark Heat Transfer Vinyl; Reflective Glow HTV; Holographic Glow HTV

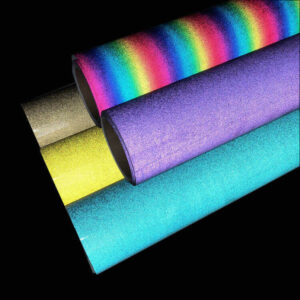

● Glitter Heat Transfer Vinyl; Reflective Glitter HTV

● Metallic Heat Transfer Vinyl

● Chameleon Heat Transfer Vinyl

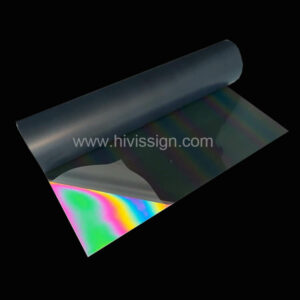

● Holographic Heat Transfer Vinyl

● Color Puff Heat Transfer Vinyl; Glow Puff Heat Transfer Vinyl

● Flock Heat Transfer Vinyl

● Light Color Change Puff HTV; Light Color Change PU HTV

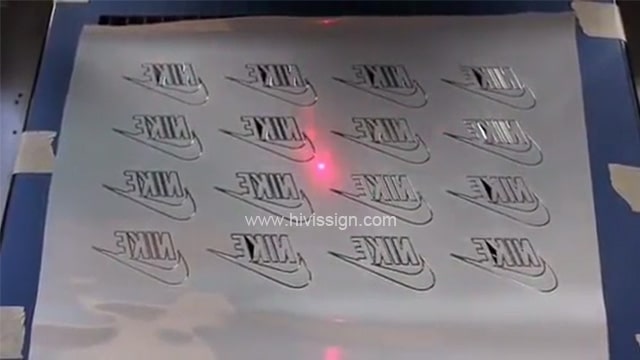

Laser cutting and plotter cutting are the main cutting methods for heat transfer material. The choice of cutting method mainly depends on the HTV material and production efficiency, such as high-stretch HTV and 3D thick types, which usually require the use of laser cutting.

In addition, European and American countries usually use plotter cutting machines, so we need to improve some iron-on vinyl materials, such as silicone heat transfer vinyl, silicone itself is a type of high elasticity, but through our improvement, it maintains a certain elasticity and can meet the plotter cutting use.

Heat transfer materials usually consist of a heat transfer vinyl layer and a plastic carrier layer.

The type of carrier film can be divided into the sticky carrier and the non-sticky carrier. Among them, for DIY users, the sticky carrier type is the first choice. Of course, some types of heat transfer vinyl are not recommended to use the sticky carriers, such as silicone HTV, because it uses sticky carriers and cannot be stored for a long time, otherwise it will affect the use.

In addition, some low-cost iron-on vinyl on the market use low-quality sticky carrier, which will mainly have carrier glue residue on the surface of the vinyl film, thus affecting its use.

It comes down to personal preference first, as heat transfer vinyl comes in a wide variety of different finishes, and heat transfer materials can only be compared and selected after you choose the finish that matches your requirements. The main considerations for the perfect HTV material are as follows:

It mainly includes easy to cut, easy to weed, and easy to transfer. These are the features that any perfect HTV vinyl must must have.

The quality of heat transfer material usually includes the quality of heat transfer vinyl and the quality of plastic carrier.

Under the premise of conforming to the finishes effect of iron on vinyl, we usually choose PU iron on vinyl, because it has better softness and elasticity than PVC and PET, and has better washing resistance. But compared with PU material, silicone heat transfer vinyl is better, so more and more children’s products and high-quality clothing will choose silicone vinyl.

According to what we mentioned in the last chapter, plastic carriers are mainly divided into sticky carrier and non-sticky carrier. But for sticky carrier, we must choose a high-quality type, which is easy to store and use.

The rich color of heat transfer material is a very important factor that allows heat transfer vinyl to be widely used, because the rich color of the material allows the colorfulness of the logo to be guaranteed.

However, for many low-priced HTV vinyls in the market, their colors seem to be listless and lack of vividness. So when purchasing, we strongly recommend you to ask your supplier to send you samples for comparison first, instead of comparing prices directly.

Printable heat transfer materials usually consist of the heat transfer film and the backing release liner.

Non-printable heat transfer material consists of the heat transfer film and the plastic carrier on top.

Printable heat transfer materials are usually PU white, reflective silver and reflective rainbow.

Non-printable heat transfer materials are available in a wide range of colors

The application of printable HTV material is a bit more complicated, it requires printing, then cutting the pattern with an edge cutter, transferring the pattern to an adhesive carrier film, and finally heat pressing the pattern to the fabric.

The application of non-printable HTV materials is very simple. After cutting the pattern directly with the plotter, the pattern can be transferred to the fabric by heat pressing.

HTV materials and self-adhesive vinyl materials are widely used in life. But their application objects are different.

HTV vinyl are mainly used in various fabrics such as shoes, clothing, hats, bags, etc.

Self-adhesive vinyl are mainly used on hard surfaces, such as cars, helmets, cups, drawing boards and other hard surfaces.

But they also have something in common, both need to use a plotter to cut the desired pattern.

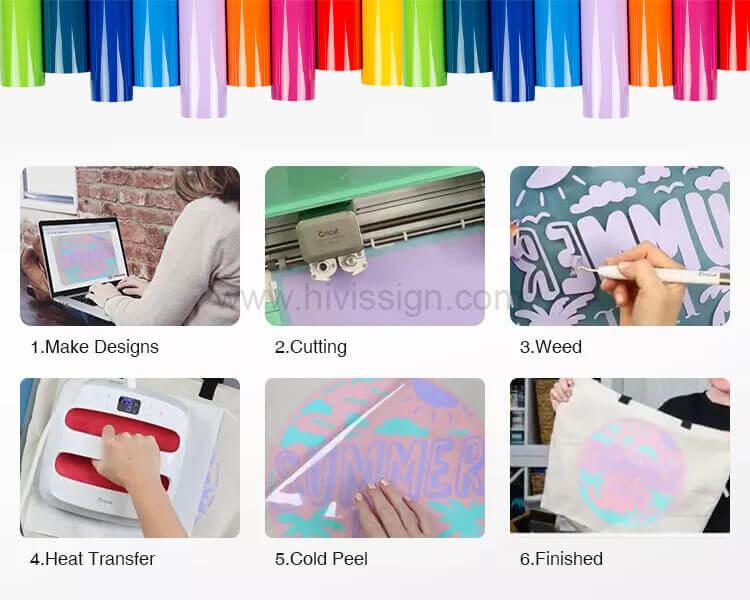

Step 1.Design an image you want by using computer design software.

Step 2.Using a plotter machine ,cut in mirror image.

Step 3.Weed the useless film around the image.

Step 4.place the front image in the place where you want to transfer on the garment.

Step 5.Set a heat press machine from 150°C(302°F)to 160°C(320°F)

Step 6.Press it only for 10-15 seconds at medium pressure.

Step 7. Wait for the vinyl to cool and gently peel off backing.

The heat transfer vinyl mainly applies the design logo to the T-shirt fabric. It uses the backing hot melt adhesive film to bond the logo to various fabrics such as polyester, cotton, and blended fabrics through high temperature heat pressing. The following are examples of the most commonly used HTV vinyls:

● T-shirts, basketball jerseys, football jerseys

● Sportswear, Yoga Wear, Leggings, Swimwear

● Hats and caps

● shoes

● bags

● Clothes for babies and children

● And much more!

We usually select the correct heat press vinyl based on the application.

For example, for bags, we usually choose HTV vinyl made of PVC and PET, because they can choose cool finishes such as holographic and chameleon, and at the same time, the cost is lower.

If applied to T-shirt clothing, we usually choose PU HTV (of course the best choice is silicone HTV, but the cost is higher), it has good softness, is not easy to crack, and has good washability.

Therefore the prerequisite for choosing a heat press vinyl material is that we understand the specific application and then choose the most cost effective type of material.

Since we are a professional heat transfer vinyl supplier and manufacturer, we not only provide you with heat transfer products, but also your trusted product advisor. We have the following advantages:

Because we are the source manufacturer, we provide you with the ex-factory price, which saves you a lot of middleman costs.

We keep stock all year round and provide you with flexible MOQ service.

Whether you want to purchase whole rolls or custom heat transfer vinyl sheets or logos, we can provide you with custom processing.

From the production of heat transfer vinyl rolls to custom processing, we provide you with a one-stop service that offers security and convenience for your purchase.

New product research and development capabilities are our pride. It guarantees the important factor that we lead the industry. Here are some examples of our new and best-sellers for 2022:

Will studying through this guide help you to choose and apply heat transfer materials correctly? We hope our HTV material guide will help more wholesalers, importers, and DIY enthusiasts. If you have other questions or like our HTV vinyl, contact us now.

Best Retroreflective Material Supplier in China. We will provide you with one-stop retroreflective material procurement services.

We will never rent or sell your email to anyone.

If you are looking for a professional reflective material supplier in China as your partner, FLIGHT is your best choice. We provide retroreflective material that comply with ASTM D4956 standards, as well as custom vehicle reflective tapes according to your country’s traffic regulations